News

Biogas2PEM-FC ends: Final review meeting

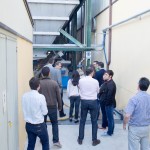

After two years of hard work the project gets closer to its end. Accordingly, a review meeting has been celebrated in Malaga 23rd and 24th October so all the project partners and the prjoect officer can review all the technical progresses achieved as well as to carry out a visit to Loja in order to visit the cooperative and see the installed prototype.

First day of the meeting was devoted to the review of the technical results. Hence, each WP carried out work, outcomes, challenges and related issues was presented. Then, the project officer provided some feedback about project execution and partners had also some Q&A time regarding final reporting of results.

During the second day of the meeting the project partners went to Loja in order to visit the cooperative where the prototype has been deployed. Firstly, a tour through the installations was conducted in order to show San Isidro facilities.

Finally, project officer and Biogas2PEM-FC consortium visited the prototype installation in order to see how all the work that has been done during this two years has evolved into a real first implementation of a future commercial product.

Biogas2PEM-FC prototype is fully deployed: operation phase started

August 07, 2014

by admin

Comments are off

After some days of hard work, deployment of the semi-pilot scale demonstrator for the project has been carried out. The platform containing the anaerobic digestion subsystem was placed beside the structure containing the other subsystems, both inside an industrial unit at SCA San Isidro at Loja. The conduits that interconnect them have been done using polymeric plastic tubing, along which proper equipment (pump, flame arresters) is inserted. The output from the pressure relief valve of the biogas tank is directed outside the building for safety reasons.

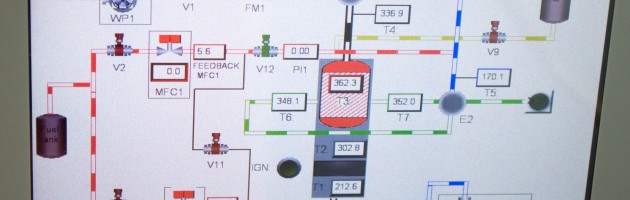

All the sensors concerning the AD subsystem have been integrated into the electrical panel, as well as the actuators (mixer, heater, pH stabilizers dosage pumps, etc.). Now, the user can check all the variables of the prototype (AD ones, Reformer ones and Fuel Cell ones) at a glance, using the Labview application where the Distributed Control System has been implemented.

The gas cylinders needed for testing and operating purposes have been secured outside the facility, and adequate protective housing has been installed to guard them against the rain. Gas conduits enter inside the building through a hole drilled into the concrete wall, while gas exhausts from both the reformer and the PEM-FC are vented outside throughout proper tubing.

Once the prototype had been installed, the digester was filled according to the proportions stated in WP1, namely 480 liters of pig manure, 80 liters of SOMW and 80 liters of OMW. Modest quantities of reagents had to be used in order to stabilize pH around 7.0 to meet the optimum conditions for the AD, studied by LEITAT during WP1. The digester was then sealed and its heating and mixing systems were activated. Biogas generation became evident after a few days of operation, and remains active till the moment, showing similar productivities to the ones observed during laboratory scale tests.

Arrival of all the prototype elements to the demo site

July 15, 2014

by admin

Comments are off

All the elements that compound the Biogas2PEM-FC project semi-pilot scale prototype are already in the demo site. During this week both the platform containing the anaerobic digestion subsystem and the structure containing the remaining elements have been transported to SCA San Isidro, at Loja (Granada), where the prototype will be finally deployed.

An adequate space had been reserved in one of the industrial bays of the olive mill. A forced ventilation system is available in this facility, as it is partially used to store fertilizers. Transportation of structures and needed gas cylinders was done using lorries. Unloading was performed throughout the loading dock of the facility. Both platforms had been equiped with wheels to ease their placement inside the industrial unit.

During the next few weeks final integration works will take place at the cooperative. Once the prototype deployment is complete and it is fully operative, the digester vessel will be loaded up with raw residue to start the anaerobic digestion process. Simultaneously, and while the generated biogas fulfills the gasometer, other tests will be conducted over the reforming unit and the fuel cell, using artificial fuels from gas cylinders.

Integration of reforming and fuel cell subsystems

July 03, 2014

by admin

Comments are off

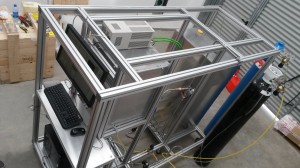

Idener has just finished the integration of two out of the three main subsystems that compound the Biogas2PEM-FC semi-pilot scale prototype. After 3 weeks of work at their facilities both the reforming subsystem and the fuel cell subsystem have been mounted over a single structure made of 45×45 mm aluminium profiles, designed specifically for that purpose. The conduits between them and to vent have been installed using stainless steel tubing. Proper manual valves, electrovalves, check valves, flame arresters and water trap for condensates have been inserted along the tube. A flow meter placed inmediately before the anode input allows the user to verify the fuel flow and to stablish desired setpoint for it.

Distributed control system (consisting of a PC and an electrical panel containing acquisition boards, fuses and safety switches) has been also integrated within the supporting structure, as well as the electronic DC load. Gas sensors have been included for safety reasons to detect any eventual hydrogen or biogas leak. An IP video camera is placed on top of this structure, so that it is possible to visualize the state of the load or other surrounding elements, such as the gasometer once it is installed beside the structure.

This DCS includes a complete control system for the fuel cell, allowing its manual or automatic operation. It has been built using Labview and comprises the acquisition of sensoring data, the calculation of the control actions to be taken and its translation to physical signals. The DCS allows autonomous dairy datalogging and it can be operated remotely.

In the next week the structure will be moved to the demo site for its definite deployment and final integration with the anaerobic digestion subsystem.

Idener receives the reforming unit from Helbio

June 18, 2014

by admin

Comments are off

The reforming subsystem for the Biogas2PEM-FC project arrived to Seville last week. Helbio has developed a compact unit able to transform a suitable source of biogas (or pure methane) into a reformate gas providing 0.8, 1.0 or 1.2 Nm3 of hydrogen per hour. The system is fully integrated and has its own PLC that controls the whole reforming procedure once it is launched. The user can select the type of fuel input, stablish desired operating point and supervise the different process variables throughout a LCD tactile screen placed in the frontal panel of the reformer.

The reformer uses part of its biogas input to perform combustion processes so that the temperature needed for some chemical reactions can be reached. It also consumes demineralized water to generate the steam for the water gas shift reactions and nitrogen to inertize the conduits after each procedure.

In order for the reformer to be integrated and controlled by the DCS (Distributed Control System), the Fatek PLC has been equipped with a ModBus module that can be configured to periodically send the values of the different variables associated to the reforming process (temperatures, pressured, mass flows, alarms etc.)

Helbio has also supplied a couple of external vessels containing the best suited filtering elements according to results from WP2. Generated biogas passes through this filters, so that a considerable fraction of CO and other kinds of impurities are removed. Such a cleaned biogas can be then used to feed the reformer.

Idener is already working in the construction of an aluminium structure to integrate the reformer and the fuel cell, with their associated conduits, valves and controls.

PowerCell’s customized PEM Fuel Cell arrives to Idener’s HQ

April 15, 2014

by admin

Comments are off

Last Friday, the 11th of April of 2014, the fuel cell for the Biogas2PEM-FC was received at Idener’s HQ. Since a couple of months ago, PowerCell and KTH have been working together in the construction of the complete Fuel Cell Subsystem. The main element of it is, obviously, the fuel cell itself. It consists of a 20-cells S1 model whose membranes have been modified, according to WP3 results, in order of be able of handling the level of impurities that might appear within the produced reformate gas.

This fuel cell comes along with the rest of auxiliary equipment, including an air mover to pump oxygen into the cathode, a radiator with its corresponding fan to dissipate generated heat, an air bleed to further reduce CO molar fraction present within the fuel, a coolant pump to refrigerate the fuel cell, a heat exchanger to equilibrate the fuel temperature and, finally, an humidifier to meet moisture requirements in the cathode side.

The received subsystem includes a series of pressure and temperature sensors to get feedback of the state of the conduits, which allows the user to operate controlled variables until desired set-points are reached. Finally, the fuel cell includes a Cell Voltage Monitoring device, which periodically measures and sends, via CAN bus, updated voltage data for each one of the 20 cells of the stack.

Idener is already working in the control and integration of the Fuel Cell with the other subsystems to deploy the complete semi-pilot scale prototype.

Prototype preliminary design is ready and construction work is in progress

March 11, 2014

by admin

Comments are off

The preliminary design for the modular prototype to be installed in the selected olive oil mill is now finished. Accordingly, construction work has started and all the consortium is allocating a huge amount of effort in order to produce the device that will be deployed and tested in the upcoming months. This issue will allow the consortium to further validate project concept and retrieve important and useful information of process performance in a real environment.

R&D work at lab scale is almost completed for main process stages

January 25, 2014

by admin

Comments are off

Biogas2PEM-FC project partners have been working in the lab these months in order to complete the R&D technical work required as for the development of the project solution. Concerning main stages of the process, anaerobic digestion, reforming and PEM-FC operation have been optimised.

As for the anaerobic digestion process, main results are related to the selection of the best available pre-treatment strategy, the selection of operational conditions (temperature, mixture of wastes and substrates, study of possible inoculums, etc, etc) and the study of the potential use of the digestate as fertiliser.

Regarding the reformer, main results achieved are related to biogas purification strategies, to the developments of catalysers in order to enhance reforming process performance and to the study of the best option for reformate treatment in order to meet PEM-FC specifications.

Finally, PEM-FC operation under different conditions has been studied. Additionally, different MEAs have been studied and effect of different impurities has been deeply analysed.

All the information produced through this work (that is related to WP1, WP2 and WP3) is now being used as for the design and construction of the modular prototype. after its implementation in the already selected olive mill cooperative the aforementioned information will be further used for defining the set-points of the device.

Olive oil mill cooperative selected for project concept validation

Biogas2PEM-FC project concept is expected to be validated at a real environment, specifically in a real olive oil mill cooperative. This issue will provide soundness to the project since it will allow to have very important information about the real performance of the process herein proposed and the real implications and interactions when it is deployed in a real facility.

As for such an end, project partner FAECA has selected an olive oil mill cooperative located in the south of Spain. As for such a cooperative a preliminary study has been carried out and wastes has been characterised. Within the upcoming months, the prototype construction will finished and then this modular device will be further installed and operated.

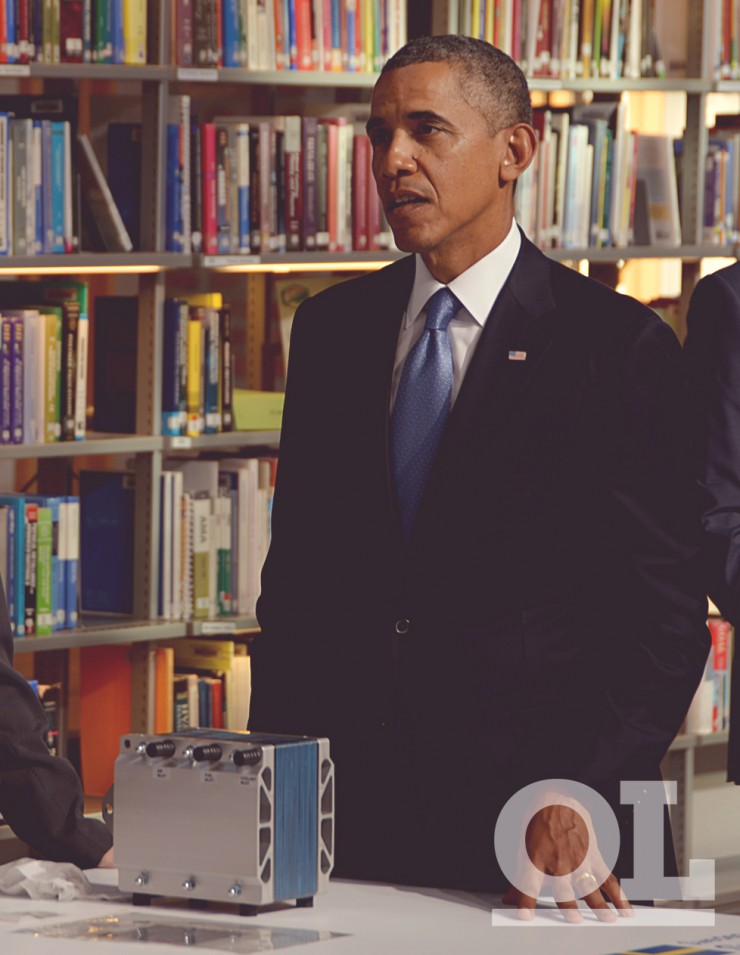

Happy birthday Biogas2PEM-FC! The project has been carried out during one year

Biogas2PEM-FC project has been running during one year. Through this time a lot of technical work has been carried out in the main stages of the proposed solution for olive mill waste valorisation. In addition, successful cases of dissemination activities such conferences attendance or Obama meeting KTH have been carried out.

Furthermore, the second semester meeting took place, providing the consortium the chance to exchange important information and deeply plan upcoming activities. This issue is very important since the prototype design, construction and deployment is fast approaching and having good results will provide evidence of the reliability and feasibility of the project concept.

Obama meets KTH

September 15, 2013

by admin

Comments are off

Barack Obama has visited KTH in order to know more about current emerging technologies, being fuel cells one of them. Since the department from KTH focussed on such an area acts as one of this Project RTD performers, Göran Lindberg and Carina Lagergren had the chance of sharing with him main project aim and objectives. Additionally, they showed him a fuel cell stack from Porwercell, one of the participating SMEs, thus providing an exceptional dissemination way of this project results.

More information can be found at:

Dissemination activities

July 15, 2013

by admin

Comments are off

Biogas2PEM-FC consortium is glad to announce that both abstracts that were sent to Wastes 2013 have been accepted. Specifically, IDENER will present a poster and LEITAT will carry out an oral presentation. In addition, KTH will also present Biogas2PEM-FC project results at the European Fuel Cell Conference to be held in Rome by the end of 2013. The aforementioned abstracts as well as the poster to be presented can be found at the “Media” section under the tab “Publications”.

Dissemination activities

June 15, 2013

by admin

Comments are off

Although at this early stage there are not enough sound results to be disseminated, partners from project consortium have continued disseminating the project idea and main outputs from the project. As an example, two abstracts have been submitted to the Wastes 2013 Congress to be held in Braga in September.

First interesting results regarding Olive Mill waste valorisation have been produced

March 15, 2013

by admin

Comments are off

Project execution goes ahead and partners keep working on their tasks, thus producing interesting preliminary results concerning the olive mill waste valorisation. Research focus has been placed in the three main technologies that compose Biogas2PEM-FC proposed solution, namely: anaerobic digestion, reforming and PEM-FC use. Anaerobic digestion related research has been focused during these months in the study of different inoculates and/or co-substrates for the optimization of methane production. Additionally, research for the use of pre-treatment technologies has also beeg conducted. As for the reforming technologies, activities about developing strategies for biogas purification have been carried out, being also started the tasks related to the development of optimum catalysts and to the study of possible strategies for the pre-treatment of the reformate. Finally, PEM-FC investigations have been related to the study of different operational conditions and how impurities affect fuel cell performance.

Biogas2PEM-FC Kick-off meeting in Sweden

December 20, 2012

by admin

Comments are off

The Biogas2PEM-FC kick-off meeting took place at Powercell Sweden AB facilities on December 18th. Please find further information in “Events” section.

Arrangements for samples collection started

December 15, 2012

by admin

Comments are off

Since the project started in November, arrangements for samples collection at the olive mill facility selected by FAECA has already started. This issue will allow LEITAT to characterize such a waste in order to provide info for the WP1, thus producing the project deliverable “D1.1 Report on OMW characterisation and definition of key parameters for optimal AD performance”

Events

Wastes 2013 – 11-13 September 2013

September 11, 2013

by admin

Comments are off

IDENER and LEITAT as RTD performers from this project will be presenting project results at Wastes 2013. Such a conference is expected to be a platform for the scientists and industries from the Waste Management and Recycling sectors from around the world, to share experiences and knowledge with all who attend. Discussions regarding the balance between economic, environmental and social outcomes will be carefully addressed. The development of innovative techniques, tools and strategies on how wastes can be transformed into good ideas, improving both the overall environmental performance and the understanding of the industry impact on the environment, as well as the options analysis for its improvement are key objectives of the event. Wastes2013 –Wastes 2013

European Fuel Cell conference (EFC13) – 11-13 December 2013

September 10, 2013

by admin

Comments are off

KTH as RTD performer from the project will present main project results in EFC13. EFC13 will promote all preliminary experience of real-life applications of fuel cells or fuel cell-based products. Accordingly, a specific track named “Approaching the market” has been introduced. In addition, the event will pool research activities on the use of fuel cells for producing chemicals taking advantage of anodic and cathodic local conditions to enhance specific reactions for the production of H2, CO, H2O etc. The core part of the event will stay focused on fuel cells development, tests and modelling as well as experiences on innovative fuels, fuel processing and system design. All environmental issues approached through fuel cells will be part of the “decarbonizing society” track. New ideas will offer the opportunity to reflect on the future of fuel cells and stimulate a different way of seeing today’s solutions. To support the dissemination activities of national and international projects (e.g. FCH-JU), a specific session will be introduced to allow the presentation of project progress and compare results. European Fuel Cell Conference –European Fuel Cell

Biogas2PEM-FC first semester meeting

May 15, 2013

by admin

Comments are off

Project consortium has met as for the First semester meeting in order to discuss and evaluate project on-going as well as to share main project results. Additionally, expectations and work to be done during the following semester have been discussed in order to ensure a proper project execution. The second semester meeting will take place hopefully between October-Novermber.

Biogas2PEM-FC kick-off meeting. Göteborg, Sweden

December 20, 2012

by admin

Comments are off

A very successful event was hosted by the project leader – Powercell on December 18th in Göteborg, Sweden. The Biogas2PEM-FC consortium met to clarify all the open questions regarding the project’s tasks, activities, deliverables and milestones.

Specifically, meeting agenda included a project overview and a brief introduction of participants followed by the discussion of the administrative and financial issues.

Furthermore, a detailed introduction of the Project Work Packages, interpreted by their respective leaders was made. The final part of the meeting was devoted to outline the work to be done during the following months and what will be need from each partner in order to ensure a proper project on-going and make easier the project partners cooperation.

Finally, the meeting ended with a visit to Powercell facilities and a joint group photo. All the partners are looking forward to the successful implementation of this promising European project.

- Biogas2PEM-FC Kick-off meeting joint group

Recent Posts Widget

Oct 31, 2014